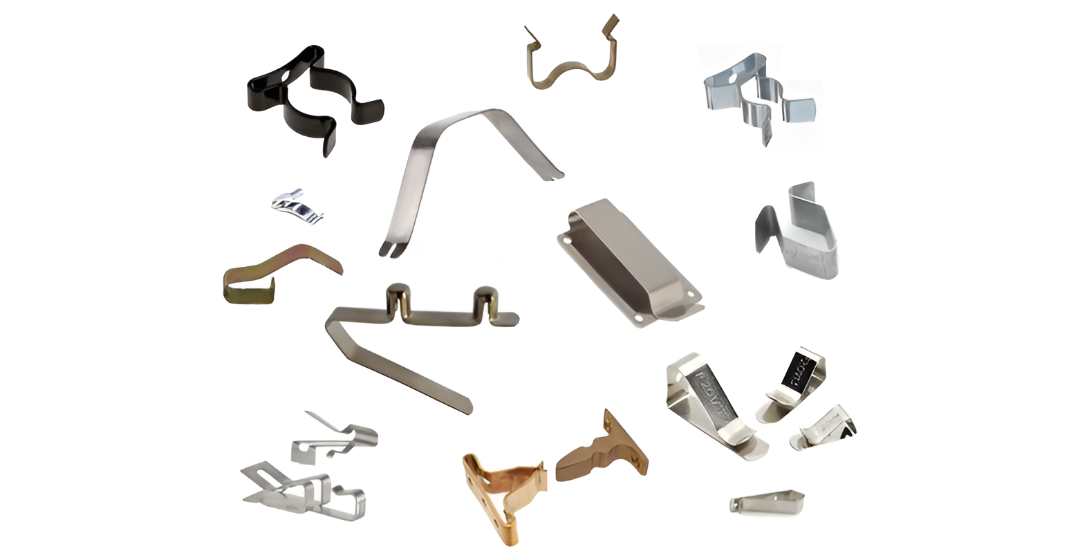

Our sheet metal bending components are formed using CNC press brake machines that ensure high accuracy and repeatability. These components are suitable for a wide range of industries including automotive, electrical, construction, and HVAC. We bend components to exact angles and dimensions based on customer drawings or CAD files, with support for small to large batch production.

We serve a wide range of industries including automotive, electrical, HVAC, and construction. Whether for structural frames, panels, enclosures, or brackets, our bending process delivers consistent quality tailored to specific applications.

Each component is formed to customer-supplied CAD files or technical drawings. We support both small and large batch production, offering fast turnaround times and maintaining strict adherence to dimensional requirements.

Benefits

- High Dimensional Accuracy: Perfect for applications requiring exact angles and alignment

- Complex Bends Possible: Custom tooling enables complex geometries and tight bends

- Strong & Durable: Maintains structural integrity during and after bending

- Cost-Effective: Minimizes welding and assembly steps

- Repeatable Results: CNC-controlled process ensures consistency across large batches

- Material Efficiency: Precision forming reduces material waste