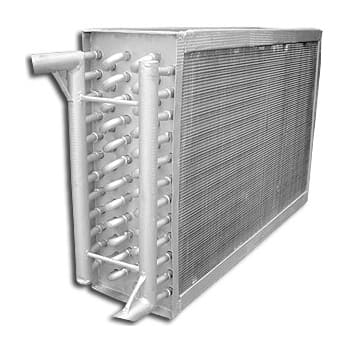

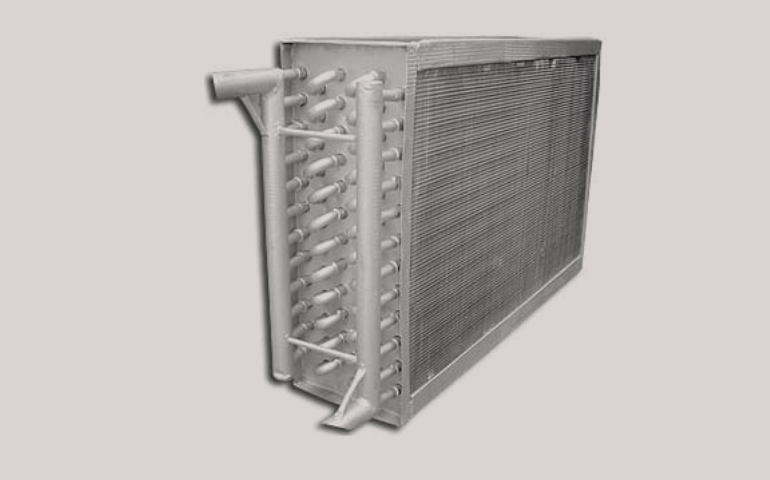

Finned tube exchangers are heat exchangers designed to improve heat transfer efficiency by increasing the surface area available for heat exchange. This is achieved by attaching fins to the exterior of the tubes, allowing the exchanger to handle greater heat loads and work effectively with fluids that have low thermal conductivity, such as air or gas. They are commonly used in applications where a compact design and high heat transfer efficiency are required.

Application:

- HVAC systems

- Power plants

- Chemical and petrochemical industries

- Air heaters and coolers

- Waste heat recovery

- Automotive radiators

Key Features:

- High heat transfer surface area

- Compact design for space-saving applications

- Suitable for gas-to-liquid and air-to-liquid heat exchange

- Durable construction for long operational life

- Efficient in low thermal conductivity fluid operations

- Customizable fin configurations and materials for specific applications

Benefits:

- Enhanced heat transfer due to increased surface area

- Energy-efficient performance

- Lower operating costs through better heat exchange

- Suitable for a wide range of industries and applications

- High performance in both heating and cooling operations